Advanced Industrial Manufacturing Solutions

encapsulates our commitment to driving forward-thinking methodologies and cutting-edge technologies within the industrial sector. Leveraging a blend of innovative techniques, automation, and meticulous quality control, we aim to redefine the benchmarks of production excellence. Our tailored solutions cater to the evolving demands of modern industries, ensuring optimized efficiency, reduced lead times, and enhanced product quality. By integrating advanced analytics, IoT capabilities, and sustainable practices, we empower businesses to navigate complexities seamlessly. Whether it’s streamlining operations, enhancing product designs, or scaling manufacturing processes, our comprehensive approach aligns with the future-forward vision of industrial manufacturing. Trust in our expertise to propel your organization towards unparalleled success in today’s dynamic marketplace.

Our Process

There are many variations of passages of Lorem Ipsum available, but the majority have suffered alteration in some form, by injected humour, or randomised words which don’t look even slightly believable.

Subtractive Manufacturing

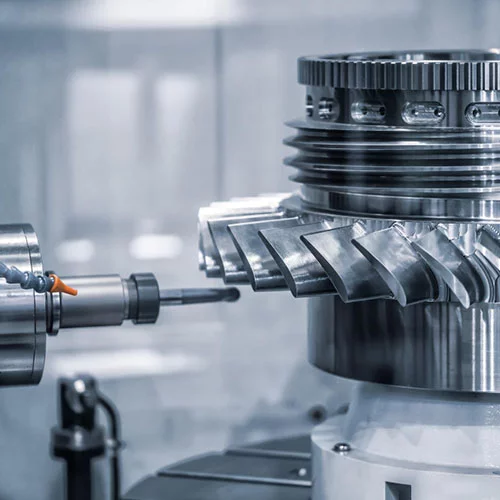

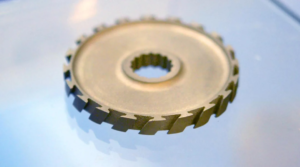

Milling

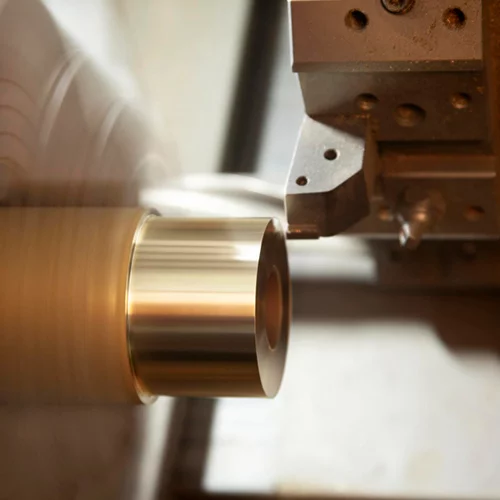

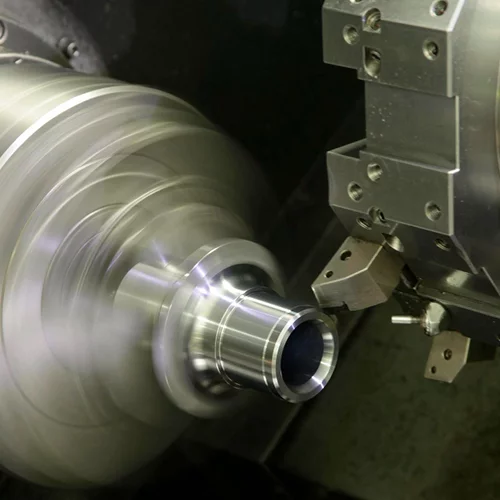

Turning

Drilling

Griding

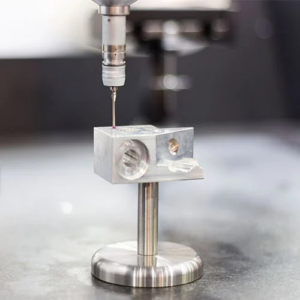

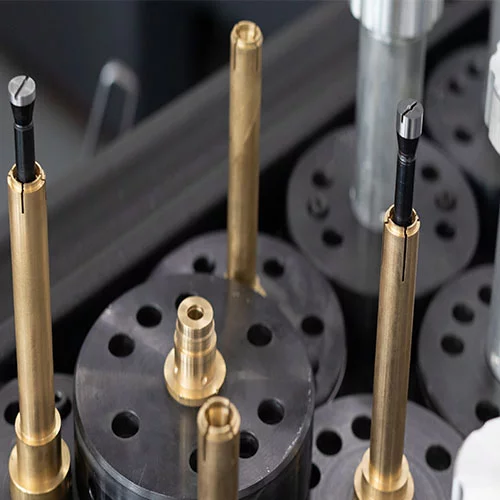

CNC Machining

We Offer A Range Of Precision Machining Solutions For Your Business Needs. We Specialize In Providing Custom CNC Machining Services To Industries Such As Aerospace, Automotive, Medical, Defense, And More. Our 3-Axis And 4-Axis CNC Machines Are Equipped With Various Toolsets To Maximize Efficiency And Production Speed. With Our Expertise And Advanced Technology, We Can Produce Complex Parts With Tight Tolerances And Superior Finishes.

Applications

- Functional prototypes

- Jigs & Fixtures

- Tool & Dies

- Production components (small and high volumes)

Specifications at Glance - Hitachi Sieki HMC

- Maximum Dimensions (4 Axis Milling): 600 mm x 500 mm x 500 mm

- Minimum Dimensions: 6.5 mm x 6.5 mm

- Machining Tolerance: 0.005 mm – 0.010 mm

- CNC turning center – Hyundai

Our CNC Machining Services Are Designed To Meet Your Unique Requirements. We Work Closely With Our Clients To Understand Their Needs, Provide Expert Advice, And Deliver Innovative Solutions That Meet Their Exact Specifications. We Can Work With A Range Of Materials, Including Aluminum, Brass, Steel, Titanium, And Plastics.

We Pride Ourselves On Delivering The Highest Quality Products And Services. Our Quality Control Processes Ensure That Every Part We Produce Meets The Highest Standards Of Accuracy And Consistency. We Use A Range Of Inspection Equipment, Including CMMs, Tool Setters, Height Gauges, And Micrometers, To Ensure That Our Products Meet Or Exceed Your Expectations.

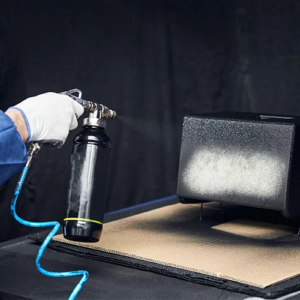

Post Processing

We Also Offer Value-Added Services, Including Finishing, Assembly, And Packaging. Our Finishing Services Include Powder Coating, Anodising, And Plating. We Can Also Provide Assembly Services To Deliver Completed Products Directly To Your Production Line.

Sheet Metal Manufacturing

Our Laser Cutting Services

Metals and Alloys: Mild steel, Stainless steel, Aluminum, Copper, and Brass. Maximum cutting size of sheet: 3000mm x 1500mm

Maximum sheet thickness: 16mm (Mild steel plate),10 mm (stainless steel), 8mm (aluminium),4mm (copper), 6mm (brass and other alloys) Our facilities are equipped with cutting edge tools which produces complex and intricate shapes with a high degree of accuracy.

1. We can produce products made from light gauge sheet metal of thickness from 0.8mm to 16mm

2. Equipped with specialized tools and dies to bend metal sheets into specific shapes and angles, controlled by computer software.

3. We offer expertise and assistance to design your product.

4. Our services covers mass production and single prototype to ensure the product meets your requirements.

5. Our software program generates a 3D model of the desired shape. Machine then uses the model to determine the correct bending sequence and angle, ensuring that each bend is precise, repeatable and accurate.

Our Welding Services Include

1. MIG welding

2. TIG welding

3. Spot welding

4. Laser sintering

We Can Integrate Fixings Such As Rivets, Nut-Inserts, Hinges, Nuts And Bolts In The Manufacturing Process. Our Longstanding Affiliations With A Broad Range Of Suppliers Allow Us To Provide A Complete Solution For Our Customers That Incorporate Machining, Electroplating And Powder Coating Services In Addition To Our Own Services.

2. Electrical Enclosures And Panels

3. Decorative And Architectural Features

3. Medical And Scientific Instruments

4. Medical And Scientific Instruments

5. Parts For Industrial Machinery And Equipment

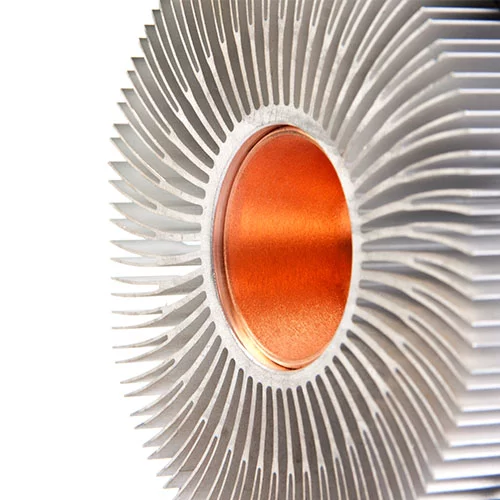

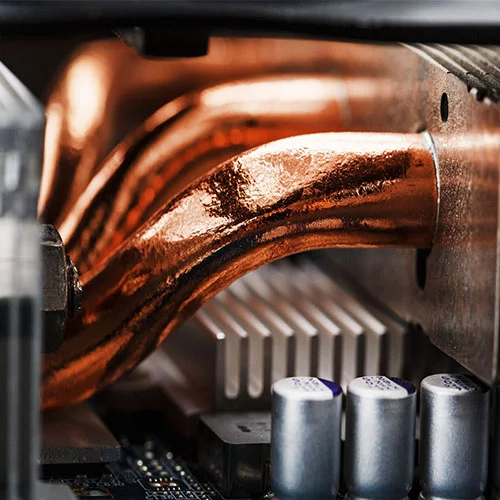

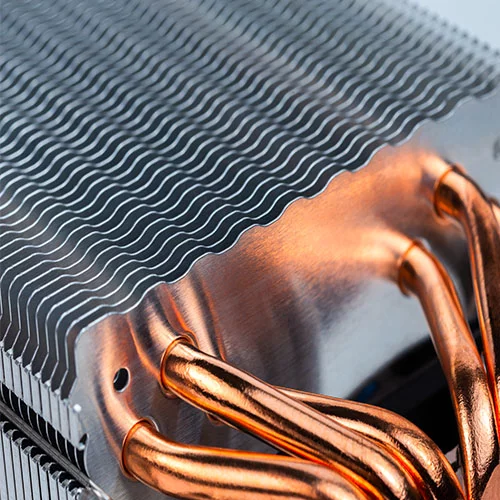

Thermal Management

Our Thermal Management Services Involve The Design, Production, And Testing Of Components Such As Heat Sinks, Heat Pipes, Cooling Fans, And Liquid Cooling Systems. Our Heat Sinks Are Used To Absorb And Dissipate Heat Generated By Any Power Devices, While Cooling Fans And Liquid Cooling Systems Are Used To Actively Remove Heat From The Device And Transfer It To A Heat Sink. In Addition To Electronic Devices, Our Thermal Management Components Are Also Used In Other Industries, Including Automotive, Aerospace, And Power Generation. For Example, We Have Recently Developed Heat Exchangers For EV Vehicles To Transfer Heat From The Engine To The Cooling System And Additionally Generate Power.

We Use Advanced Thermal Analysis Software To Simulate And Optimize The Performance Of Our Components, Ensuring That They Meet Or Exceed Our Clients’ Expectations. We Also Conduct Rigorous Testing To Ensure That Our Components Are Reliable And Durable, Even Under Extreme Conditions.

Our recent projects

high-performance battery cooling systems

We supported design and production of high-performance battery cooling systems ensuring their optimal performance and longevity, and preventing damage or malfunction.

Prototype for high power LED lighting

We delivered working prototype for high power LED lighting by designing and combining heat sinks and heat pipes that effectively dissipate heat from the LED modules in automobile industry.

simulation software

We have developed simulation software to precisely determine U-Value in custom rooms and buildings to understand better insulation required for installing heaters and coolers.

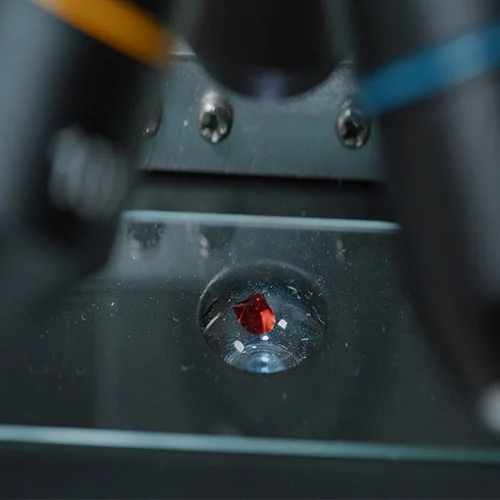

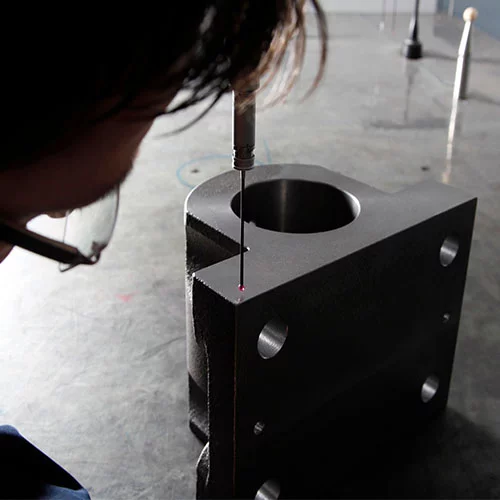

Precision Measurements

We Provide Precision Measurement Services Using Advanced CMM (Coordinate Measuring Machine) Technology, Including Optical 2D And 3D Measurement Systems. Our Team Of Experienced Professionals Is Dedicated To Providing Accurate And Reliable Measurement Solutions For A Wide Range Of Machine Parts And Components. At Our Facility, We Use State-Of-The-Art CMM Machines And Optical Measurement Equipment To Ensure That Your Parts Are Measured With The Utmost Precision And Accuracy. Our CMM Machines Are Capable Of Measuring Parts With A High Degree Of Accuracy, Allowing Us To Provide Detailed Analysis Of Even The Most Complex Geometries.

We Offer A Variety Of Measurement Solutions, Including Contact And Non-Contact Measurements

2D & 3D Measurement

Dimensional Inspection

In-Process Measurements

Surface Finish Measurements

Tooling And Mold Inspection

Geometric Dimensioning And Tolerancing

Our Team Of Experts Can Work With You To Develop A Custom Measurement Solution That Meets Your Specific Needs. We Can Provide Accurate And Reliable Measurement Data For Quality Control, Product Development, And Process Improvement. If You’re Looking For Precision Measurement Services Using Advanced CMM Technology, Including Optical 2D And 3D Measurement Systems, You’ve Come To The Right Place. Contact Us Today To Learn More About Our Services And How We Can Help You With Your Measurement Needs.

At Revaron, We Take A Collaborative Approach To Our Work, Engaging With You To Understand Your Requirements And Goals For Your Project. We Use Our Expertise And Industry Knowledge To Provide You With Innovative Ideas, And Work With You Through Every Step Of The Design Process, From Concept To Manufacturing. We Specialize In A Range Of Industries, Including Aerospace, Automotive, Consumer Products, And Medical Devices. No Matter The Industry, Our Commitment To Quality And Attention To Detail Is Unwavering.